WEL6

Air cooler

WEL6

Air cooler

WEL6002A4

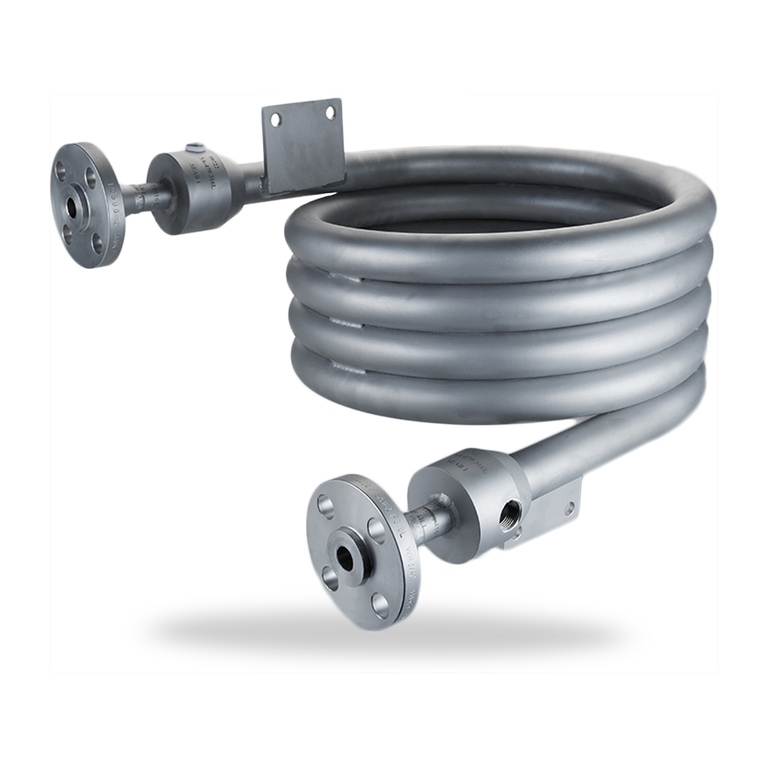

A From mechanical seal

B To mechanical seal

C Vent

D Drain

A From mechanical seal

B To mechanical seal

C Vent

D Drain

WEL6

Air cooler

Features

Heat exchangers of the WEL6000A4 range (shown here: WEL6002A4) are used to cool process/barrier fluids in seal supply circuits. The heat exchangers are made of helical, laser-welded finned tubes. The cooling medium is ambient air. It is important, therefore, for WEL heat exchangers to be installed in well ventilated places indoors or, ideally, outdoors. There is a choice of three different basic versions of the WEL6 range as well as being supplied fully assembled together with valves, base frame and other system components.

Advantages

- Operating limits up to 44 bar / 260 °C

(638 PSI / 500 °F) (tube side): suitable for a wide range of demanding operating conditions. - Can be completely vented and drained

- Seamless pipes

- Stainless steel 316/316L: high resistance to corrosive media

Standards and approvals

- API 682 / ISO 21049

- API 682 4th ed. Cat. 2/3 - 1CW-FL

- API 682 4th ed. Cat. 2/3 - 2CW-CW

- API 682 4th ed. Cat. 2/3 - 2CW-CS

- API 682 4th ed. Cat. 2/3 - 3CW-FB

- API 682 4th ed. Cat. 2/3 - 3CW-BB

- API 682 4th ed. Cat. 2/3 - 3CW-FF

- API 682 4th ed. Cat. 1 - 1CW-FX

- API 682 4th ed. Cat. 1 - 2CW-CW

- API 682 4th ed. Cat. 1 - 3CW-FB

Recommended applications

- Refining technology

- Oil and gas industry

- Petrochemical industry

- Chemical industry

- Power plant technology

Notes

PED 2014/68/EU (Design and production in accordance with EU Pressure Equipment Directive) or

ASME VIII, Div. 1 (Calculation based on ASME VIII, Div. 1 - cooler not subject to ASME stamp requirements, piping <6").

Product variants

| Designation | WEL6001A4 A001-D0 |

WEL6002A4 A001-D0 |

WEL6004A4 A001-D0 |

|||

|---|---|---|---|---|---|---|

| Type of heat exchanger | ASME | PED | ASME | PED | ASME | PED |

| Number of finned tubes | 1 | 2 finned tubes switched in parallel |

2 finned tubes switched in parallel and doubled length |

|||

| Connections | Flange 3/4", 600 lbs | Flange 3/4", 600 lbs | Flange 3/4", 600 lbs | |||

| Drain / vent connection | Flange 1/2", 600 lbs 4) | Flange 1/2", 600 lbs 4) | Flange 1/2", 600 lbs 4) | |||

| Allowable pressure1) | 44 bar (638 PSI) |

44 bar (638 PSI) |

44 bar (638 PSI) |

44 bar (638 PSI) |

44 bar (638 PSI) |

44 bar (638 PSI) |

| Allowable temperature process/barrier medium side (tube side) 1) |

-29 °C … +260 °C (-20 °F … +500 °F) |

-29 °C … +260 °C (-20 °F … +500 °F) |

-29 °C … +260 °C (-20 °F … +500 °F) |

|||

| Cooling capacity (kW)2) | 1.5 | 2 | 3 | |||

| Cooling capacity (kW)3) | 0.9 | 1.4 | 1.8 | |||

| Volume (liters) | 0.7 | 1.1 | 1.5 | |||

| Metal parts | 316/316L | 316/316L | 316/316L | |||

Other versions on request.

1) Design data, permissible working values depend on the actual conditions of service.

2) Guidelines with barrier/buffer fluid water 60 °C (140 °F) – ambient temperature 20 °C (68 °F);

moved air at min. 0.7 m/s (2.3 ft/s); product flow rate 8 l/min.

3) Guidelines with barrier/buffer fluid oil 60 °C (140 °F) – ambient temperature 20 °C (68 °F);

moved air at min. 0.7 m/s (2.3 ft/s); product flow rate 8 l/min.

4) Version with screwed connection G1/2" available as an option.

Similar products

WEF6 Water cooler

Heat exchangers of the WEF6 range are used to cool process/barrier fluids in seal supply circuits. WEF6 heat exchangers are fully compliant with API 682 4th edition regulations. The process/barrier medium is directed through the tube, and the cooling medium is directed through the shell.

Venting and draining of the process/barrier medium side as well as the cooling water side is ensured. In addition, the heat exchangers can also be combined with a temperature instrument in the supply line to the mechanical seal (optional in accordance with API 682 4th edition).

Venting and draining of the process/barrier medium side as well as the cooling water side is ensured. In addition, the heat exchangers can also be combined with a temperature instrument in the supply line to the mechanical seal (optional in accordance with API 682 4th edition).